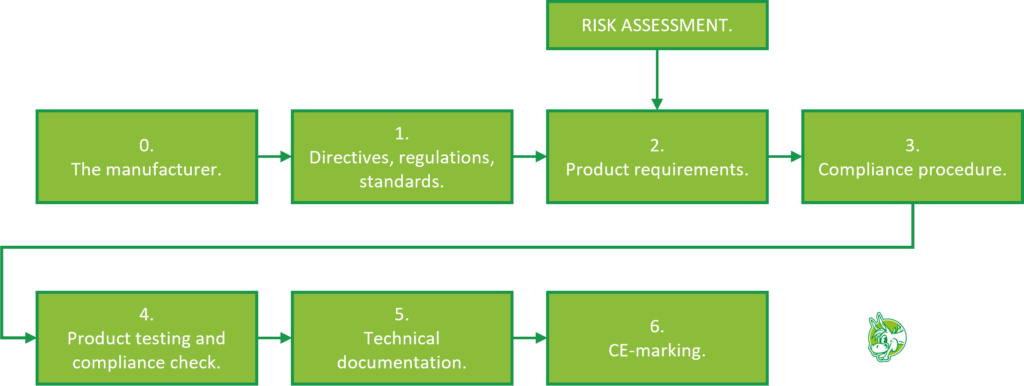

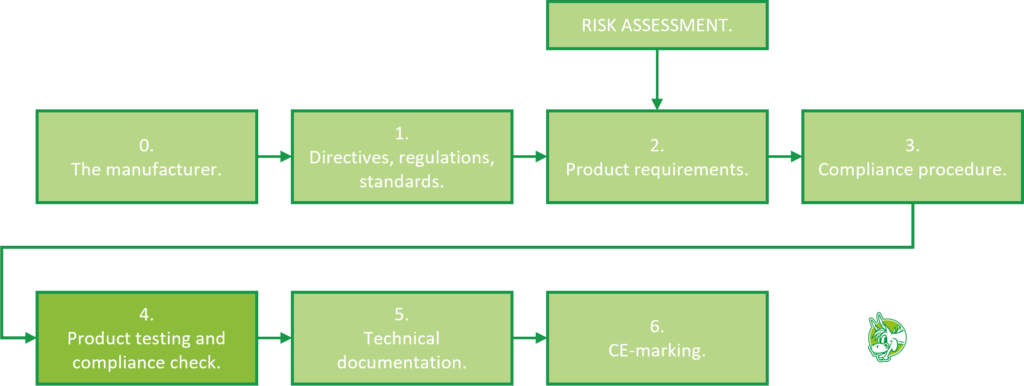

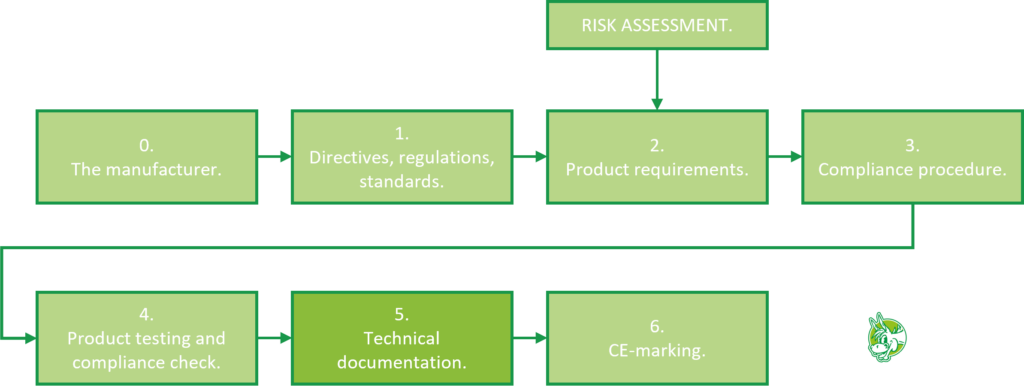

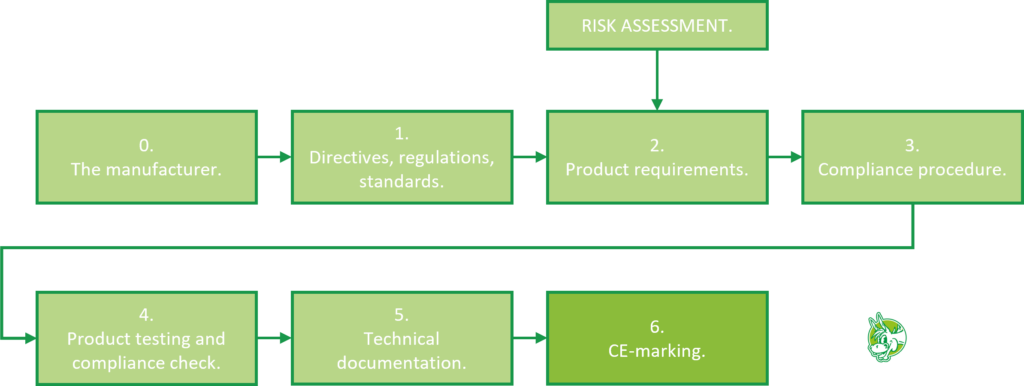

CE-Assistant: This is how it works

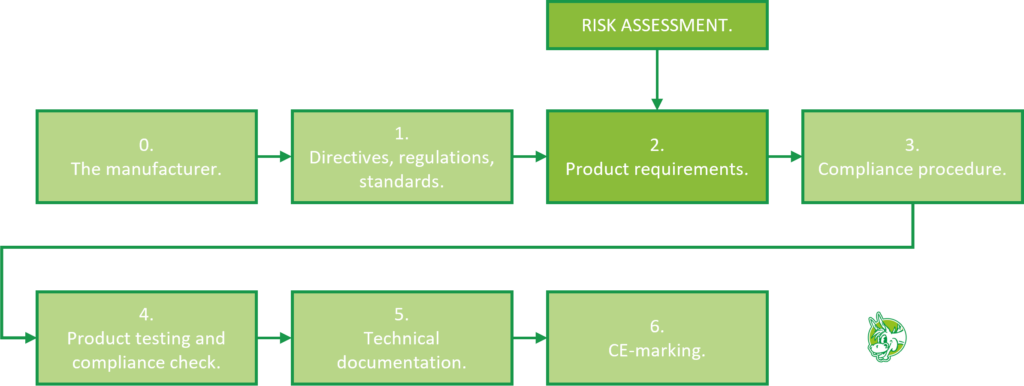

CE-Assistant slices up a CE-marking process in these steps:

These steps are prescribed by the European Commission. You can read about that here.

Step 0: Decide who will be the manufacturer

According to the Machinery Regulation 2023/1230 the definition of a manufacturer is:

(18) ‘manufacturer’ means any natural or legal person who:

- manufactures products within the scope of this Regulation or who has those products designed or manufactured, and markets those products under its name or trademark; or

- manufactures products within the scope of this Regulation, and puts those products into service for its own use;

A similar definition can be found in other directives and regulations.

The manufacturer is one of the actors in the product supply chain and their obligations. This means there are more actors. Read all about those, and more, in the ‘Blue Guide’ by clicking here.

Important! If, for example, you as a machine builder produce a machine in accordance with drawings and information supplied by your customer and it has not been agreed who will be the manufacturer, you will be as the machine builder. You market the machine. So make clear agreements (for example in the order confirmation) as to who will be regarded as the manufacturer.

The manufacturer assumes all obligations under the relevant directive(s) and/or regulation(s) and therefore completes all steps in the CE-marking process.

The manufacturer role also changes when different machines are assembled. In the examples below, the actor above the dotted line is the supplier, the customer and/or enduser is under the dotted line.

*pc means Partly Completed.

When you make a substantial modification to a machine, you become its manufacturer.

Substantial modification is defined in the Machine Regulation 2023/1230 as follows:

(16) ‘substantial modification’ means a modification of machinery or a related product, by physical or digital means after that machinery or related product has been placed on the market or put into service, which is not foreseen or planned by the manufacturer, and which affects the safety of that machinery or related product, by creating a new hazard, or by increasing an existing risk, which requires:

- the addition of guards or protective devices to that machinery or related product the processing of which necessitates the modification of the existing safety control system; or

- (b) the adoption of additional protective measures to ensure the stability or mechanical strength of that machinery or related product;

Carrying out a substantial modification results in:

Article 18

Other cases in which obligations of manufacturers apply

A natural or legal person that carries out a substantial modification of machinery or a related product shall be considered to be a manufacturer for the purposes of this Regulation and shall be subject to the obligations of the manufacturer set out in Article 10 for that machinery or related product or, if the substantial modification has an impact on the safety of only machinery or a related product that is part of an assembly of machinery, for that affected machinery or related product, as demonstrated in the risk assessment.

The person who carries out the substantial modification shall in particular, but without prejudice to other obligations set out in Article 10, ensure and declare on its sole responsibility that the machinery or related product concerned is in conformity with the applicable requirements of this Regulation and shall apply the relevant conformity assessment procedure as provided in Article 25 (2), (3) and (4) of this Regulation.

A non-professional user who carries out a substantial modification to his or her machinery or related product, for his or her own use, shall not be considered to be a manufacturer for the purposes of this Regulation and shall not be subject to the obligations on the manufacturer set out in Article 10.

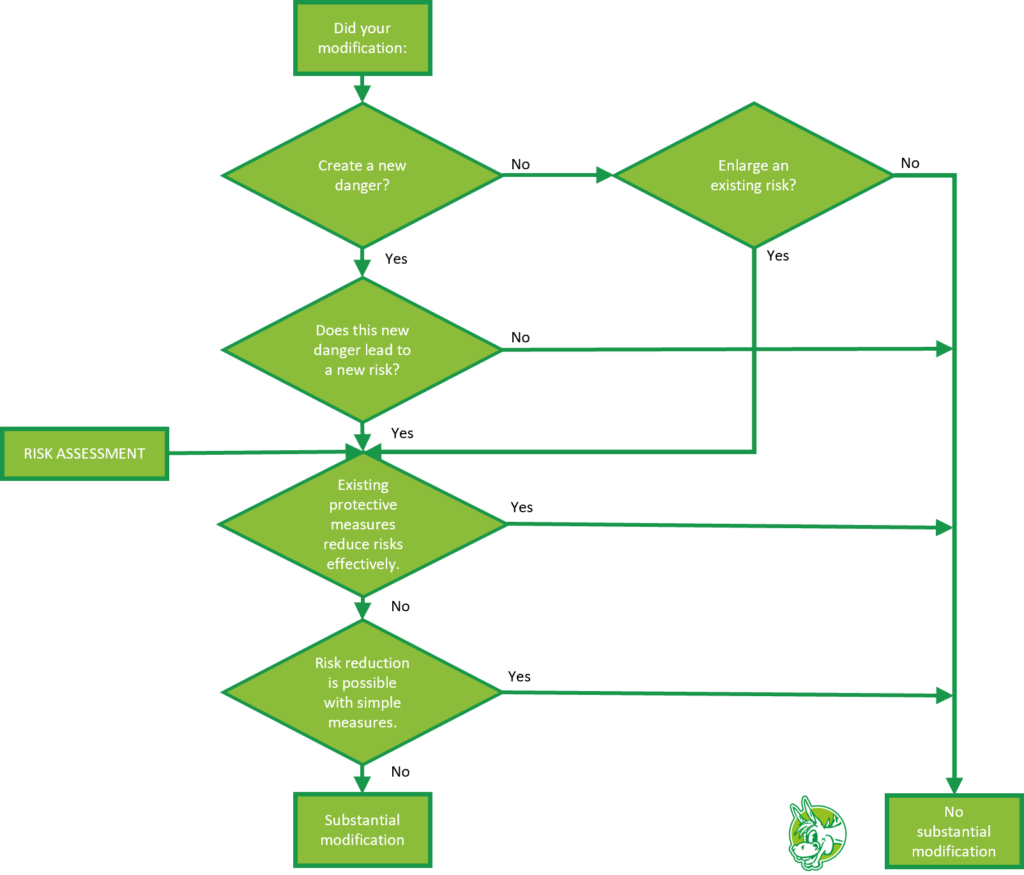

The flowchart below is an aid to determine whether or not a modification is substantial. The Netherlands labour Authority composed a clear procedure how to deal with substantial modifications. It is in Dutch and you can read it here.

The result of step 0 is that we now know who will be the manufacturer as stated in the Machine Regulation 2023/1230.

Step 1: Identify the applicable directive(s)

and/or regulation(s) and harmonised standards

Directives and regulations are European laws. The main difference between the two is that regulations are directly binding on EU member states and directives have an obligation to adapt national legislation to that directive.

For example, the Machinery Directive has been applied in the Netherlands in the Machines Commodities Act Decree. The Machinery Regulation will make the Machines Commodities Act Decree redundant in 2027.

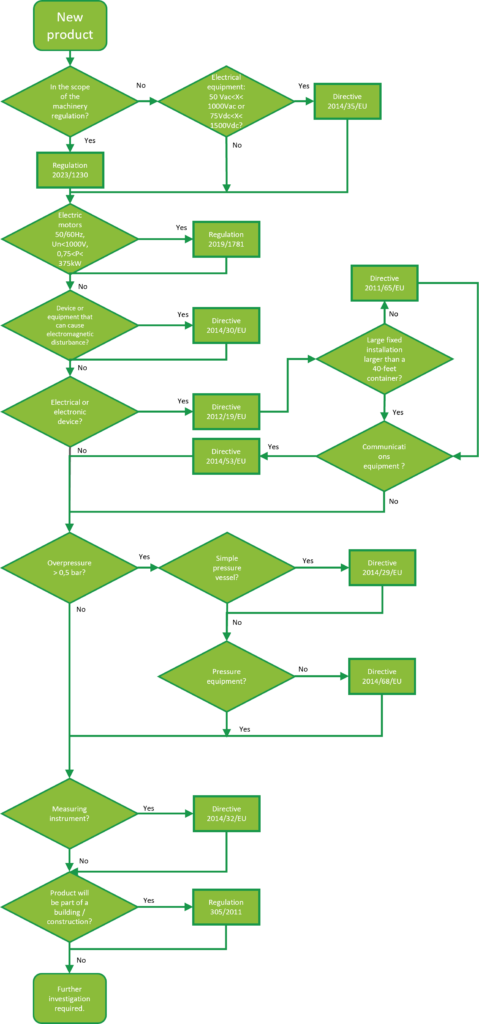

There are many guidelines and regulations, the flowchart below helps you to determine which guidelines a machine must comply with. Notice! There are more guidelines and regulations than those in the diagram. The CE-Assistant tool takes all guidelines and regulations into account. Need an up-to-date list of product legislation? Click here.

Number

Name

Full title

Included in flowchart?

2012/19/EU

Waste Electrical and Electronic Equipment (WEEE) Directive

DIRECTIVE 2012/19/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 4 July 2012 on waste electrical and electronic equipment (WEEE)

Yes

2006/66/EG

Batteries and accumulators waste

DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC

No

2011/65/EU

hazardous substances in electrical and electronic equipment

DIRECTIVE 2011/65/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

Yes

305/2011

Construction products

Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC Text with EEA relevance

Yes

1935/2004

Food contact regulation

Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC

No

2014/68/EU

Pressure equipment

DIRECTIVE 2014/68/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 15 May 2014 on the harmonisation of the laws of the member States relating to the making available on the market of pressure equipment

Yes

2014/29/EU

Simple pressure vessels

DIRECTIVE 2014/29/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of simple pressure vessels

Yes

2019/1781

Ecodesign requirements for electric motors and variable speed drives

Commission Regulation (EU) 2019/1781 of 1 October 2019 laying down ecodesign requirements for electric motors and variable speed drives pursuant to Directive 2009/125/EC of the European Parliament and of the Council, amending Regulation (EC) No 641/2009 with regard to ecodesign requirements for glandless standalone circulators and glandless circulators integrated in products and repealing Commission Regulation (EC) No 640/2009

Yes

2014/30/EU

Electromagnetic compatibility EMC Directive

DIRECTIVE 2014/30/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 on the harmonisation of the laws of the member States relating to electromagnetic compatibility

Yes

2014/35/EU

Low Voltage Directive

Directive 2014/35/EU of the European Parliament and of the Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of electrical equipment designed for use within certain voltage limits (recast) Text with EEA relevance

Yes

2014/33/EU

Lift and lift safety components

DIRECTIVE 2014/33/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 on the harmonisation of the laws of the Member States relating to lifts and safety components for lifts

No

2023/1230

Machine regulation

REGULATION (EU) 2023/1230 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 14 June 2023 on machinery and repealing Directive 2006/42/EC of the European Parliament and of the Council and Council Directive 73/361/EEC

Yes

2014/32/EU

Measuring instruments

DIRECTIVE 2014/32/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of measuring instruments (recast)

Yes

2014/31/EU

Non-automatic measuring instruments

DIRECTIVE 2014/31/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of non-automatic weighing instruments

No

2014/53/EU

Radio Equipment Directive

DIRECTIVE 2014/53/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 16 April 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of radio equipment and repealing Directive 1999/5/EC

Yes

About standards

Standards are not laws. Compliance with harmonised standards is therefore certainly not an obligation. However it is wise to do so: Standards are seen as the current state of science and technology. Using it therefore proves that your machine or product is up-to date. Regulations and directives always cite harmonized standards in their text. The Machinery Regulation does this as follows:

CHAPTER III

CONFORMITY OF PRODUCTS WITHIN THE SCOPE OF THIS REGULATION

Article 20

Presumption of conformity of products within the scope of this Regulation

Complying with standards is much faster, more convenient and more accepted in the market than drawing up a methodology yourself to prove compliance with Annex III (essential safety and health requirements regarding the design and construction of machines and related products).

The CE-Assistant tool consequently takes into account current harmonized norms and standards.

There are more standards than directives and regulations together. Standards indicate the current state of technology and become, for that reason, outdated quickly. Always check the validity of a standard before use. Standards are created by so-called standard or technical committees: substantive experts in the area covered by the standard.

Each standard indicates in the foreword and/or introduction which committee has examined it and whether the standard is an A, B or C standard:

- A-standards (basic safety standards) which provide the basic concepts, design principles and general aspects that can be applied to all machines. An example is NEN-EN-ISO 12100:2010 ‘Safety of machines – General design principles – Risk assessment and risk reduction’.

- B standards (generic safety standards) covering one safety aspect or one type of safety device that can be used for a wide range of machines:

- B1 standards that address specific safety aspects (e.g. safety distances, surface temperature, noise);

- B2 standards that address safety features (e.g. two-hand operation, locking devices, pressure-sensitive features, guards);

- C standards (machine safety standards) that cover detailed safety requirements for a particular machine or group of machines.

CE-Assistant integrates all the correct and necessary up to date standards in its application for your machinery. Need an up-to-date harmonized standards list? click here.

The flowchart below shows how B- and/or C-standards are used.

About national legislation

Although most legislation is European, Member States are often free to impose stricter or additional legislation.

This includes:

- Road Traffic Act;

- Occupational health and safety legislation;

- Mandatory inventory from the working conditions decree;

- Etc.

Checking this is therefore necessary. Requirements from this national legislation must also be applied in the design. Please mind that this check is NOT integrated in the CE-Assistant application. The reason for this is that national legislation may change fast and is often region bound.

A help to determine applicable national legislation is this YOUR Europe link.

Result of step 1: An inventory of all regulations, directives, standards and (if applicable) national/local requirements.

Step 2: Product requirements

Step 1 determines which regulations, directives, standards and national legislation apply.

In step 2, all of them will have to be reviewed so that it will be possible to determine which articles are applicable and which are not. This means a lot of reading and a good interpretation of the regulations, directives, standards and national legislation.

CE-Assistant helps you with step 2 by presenting all applicable regulations, directives, standards and national legislation in an easy to read format that can be directly used in your technical documentation. Each regulation, directive, standard and national legislation will be converted in a spreadsheet-like format in which tekst easily can be entered, not applicable articles / demands can be filtered out etc.

An example (machinery directive) of this is shown below:

Result of step 2: A full review of all regulations, directives, standards and (if applicable) national/local requirements resulting in the product requirements.

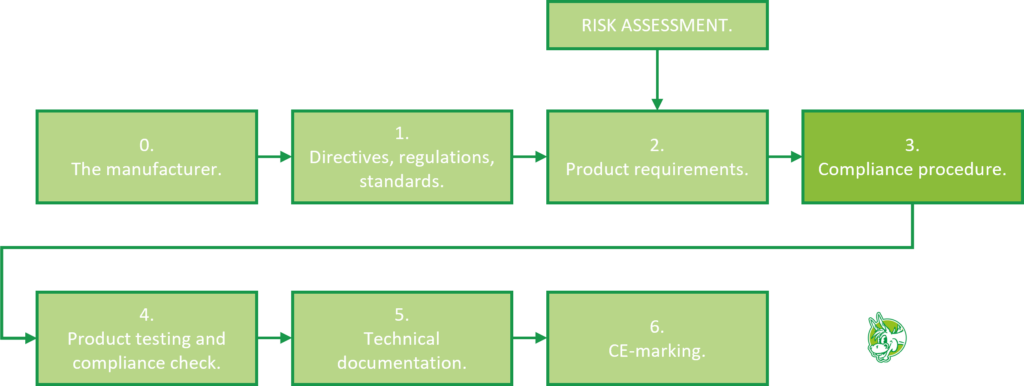

Step 3: Compliance procedure

For most products, the manufacturer is allowed to take care of the CE marking by himself.

However, there are exceptions and this has consequences for the compliance procedure that needs to be followed, whether or not a notified body should be involved, and the question whether or not specific national tests and investigations are necessary.

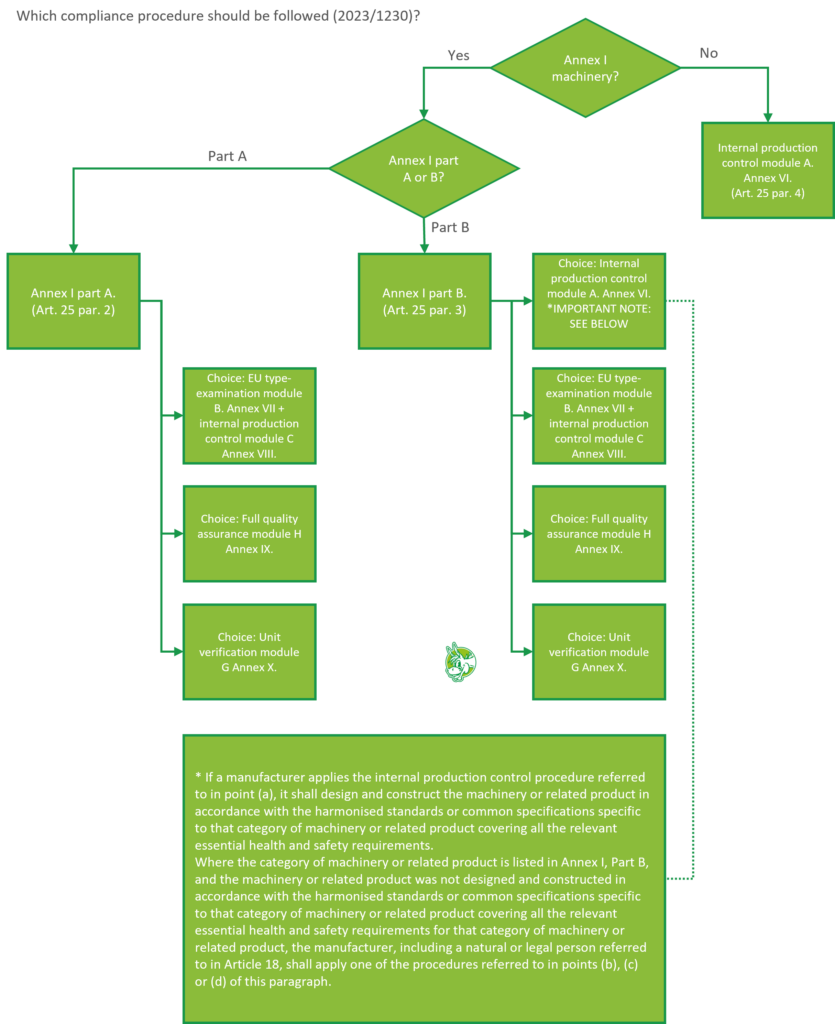

The flowchart shown below is based upon the Machinery Regulation 2023/1230 and helps you to choose the correct compliance procedure.

When the compliance procedure is chosen in the CE-Assistant application, the demands in that procedure will be converted in a spreadsheet-like format in which text easily can be entered.

Do you need a notified body? Here is a searchable list by country.

Result of step 3: A decision of the compliance procedure that needs to be followed and as a result, the concerned demands.

Step 4: Product testing and compliance check

Step 4 is about checking if the product requirements (step 2) are met in full, if all issues out of the risk assessment are covered etc. In short: Did we put the theory into practice?

Once the previous activities have been carried out consistently, the verification with the guidelines doesn’t take a lot of extra time. It is then a matter of checking whether all the previous specified actions have been carried out. In addition, it should be considered whether or not all the proof is delivered in full. The essential requirements can then be substantiated with a short summary of the actions undertaken. The whole can be illustrated with links to risk assessments, verifications of standards, checklists etc.

CE-Assistant helps you with step 4 by presenting all applicable regulations, directives, standards and national legislation in an easy to read format that can be directly used in your technical documentation. Each regulation, directive, standard and national legislation will be converted in a spreadsheet-like format in which text easily can be entered, not applicable articles / demands can be filtered out etc. See step 2 for an example. Want another example? Below you find an easy to work with checklist for robot applications (Annex G of ISO 10218-2).

Result of step 4: A check whether or not all required actions have been undertaken.

Step 5: Technical documentation

The technical documentation is necessary because it serves as ‘evidence’ in case of doubt whether or not the product is compliant with essential requirements. The justification of the manufacturer’s declaration relies in part on the existence of this documentation. The technical documentation should therefore contain all the information necessary to ensure compliance with directives, regulations, national laws and standards.

The manufacturer is obliged to submit the technical documentation to a competent authority when requested. Moreover, the technical documentation is necessary when a third party is involved (see step: Compliance procedure).

In the light of product liability this documentation is of great value to the manufacturer. Most of the documentation will often be edited while developing and manufacturing the new product during not CE-related activities. This information includes design documents, drawings, calculations, specifications etc. Much of the other information comes from the previous steps.

Machinery regulation’s Annex IV describes the mandatory components of the technical documentation.

CE-Assistant helps you by providing an Annex IV checklist and integrating your design documents, drawings, calculations, specifications, user manuals, supplier declarations etc. in the CE-marking process.

Result of step 5: Correct and complete technical documentation of the new product all in one place.

Step 6: CE-marking

The final step is drawing up the EU declaration of conformity and attaching the nameplate (with CE-logo) on the new product.